Versatile structural repair workstations designed to handle a wide range of damage, from minor dents to major frame repairs.

100 Series

A Structural Repair Workstation with

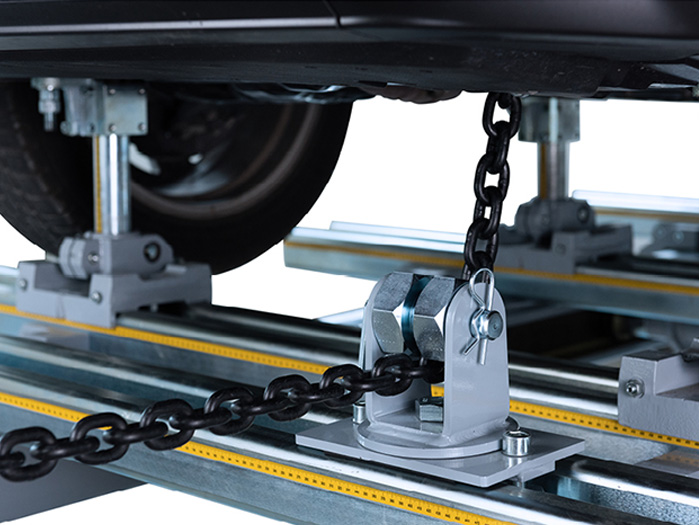

100 Series frame machines are designed to handle intense pulling. High quality materials ensure our benches are durable, guaranteeing consistent performance over extended periods of time.

The pulling column provides 10 tons of pulling force and allows for pulling angles around the entire vehicle. With 12 bench mounting locations, technicians can handle any pull from any direction.

The 100 Series is engineered to accommodate a diverse range of vehicles, including cars, trucks, SUVs, and electric vehicles (EVs), ensuring comprehensive repair solutions across various vehicle types.

Optional accessories such as telescopic pulling arms and down-pull adaptors, allow technicians to apply force in multiple directions simultaneously, enhancing efficiency and precision in complex repair scenarios.

100 Series Pairs Perfectly With the

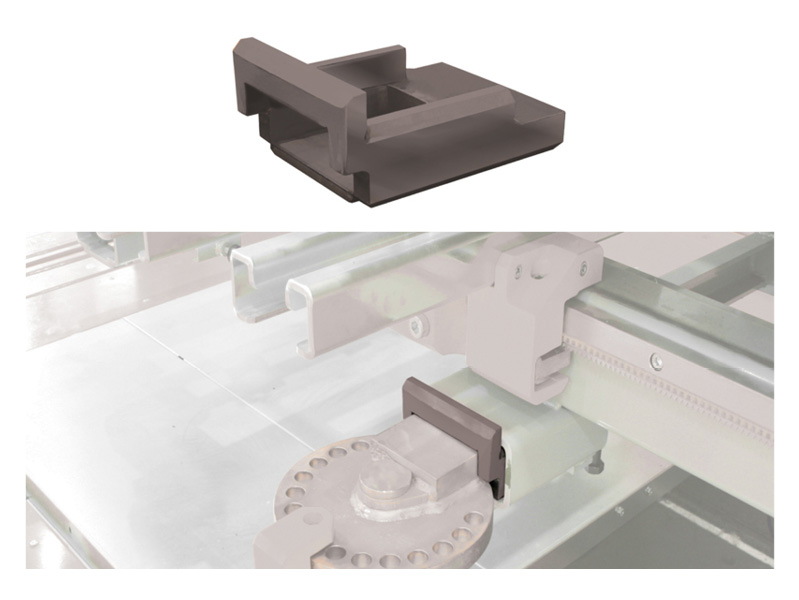

The Universal Jig System and all of the 100 Series frame machines form a powerful combination, providing collision repair technicians with a comprehensive solution for restoring vehicles to their original factory specifications. With the 3 dimensional repair capabilities of the Universal Jig System and the structural repair capabilities of the 100 Series, technicians can ensure precise and efficient vehicle repairs.

The modular design of the Universal Jig System allows for customization to fit various vehicle types and damage scenarios, complementing the 100 Series’s adaptability to unique repair needs. By streamlining the repair process, these combined systems help to improve vehicle turnaround times, technician efficiency, and provide high-quality repairs that meet OEM standards.

Together the Universal Jig System and the 100 Series offers a robust and reliable solution for collision repair facilities, enabling them to deliver exceptional results and maintain customer satisfaction.

Available in 3 different lengths

13′ (4m), 16′ 5″ (5m), 19′ 8″ (6m)

12 mounting locations, pull from anywhere with 10 tons of force.

Pull from multiple directions and angles without losing any power

Crossbars provide smooth and effortless movement.

Repair a wide range of vehicles regardless of damage type.

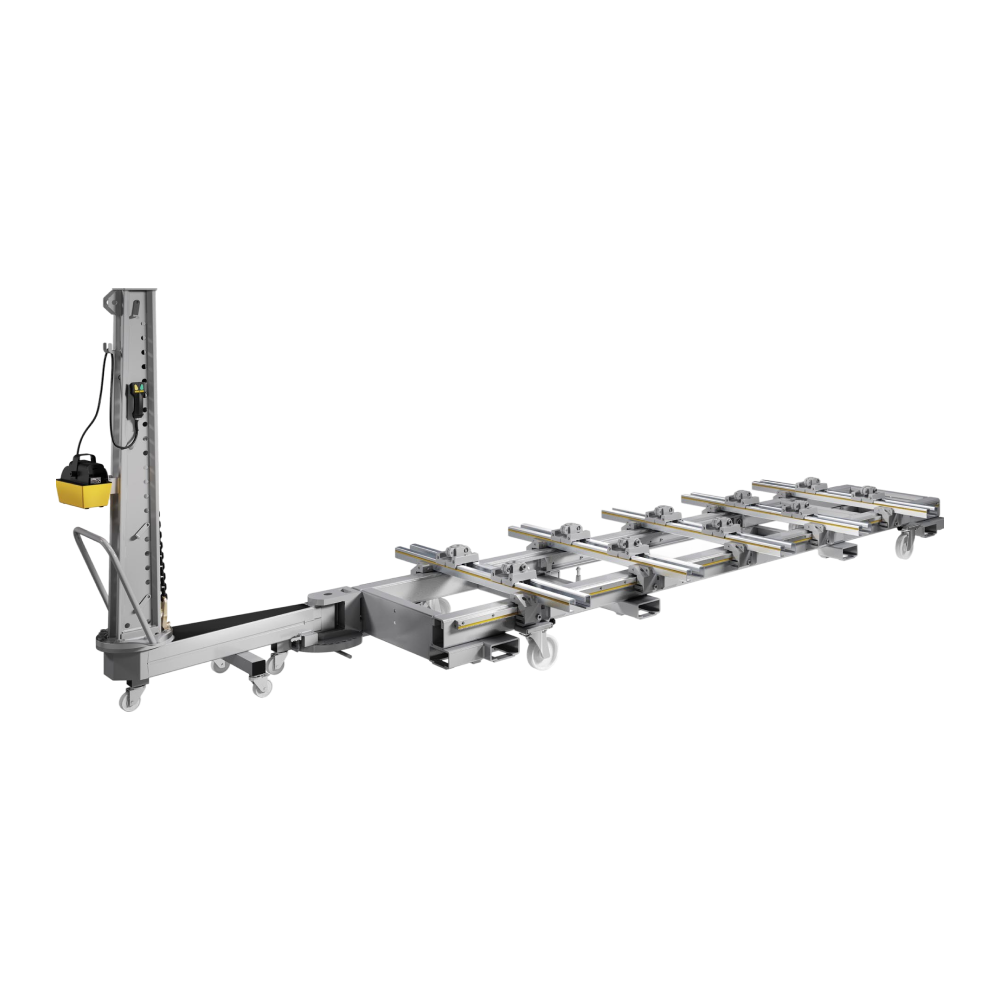

Frame Machine

The 100 TB Structural Repair Workstation is a powerhouse with 10 ton of pulling force.

| 100 TB Components: |

|---|

| Bench w/ Rack Gears |

| Pulling Column |

| 2 Crossbars |

| 4 Universal Clamps |

Frame Machine

The 102 combines the power and durability of the 102 with the flexibility of the Universal Jig System.

| 102 Components: |

|---|

| Bench w/ Rack Gears |

| Pulling Column |

| 5 Crossbars |

| Universal Jig System |

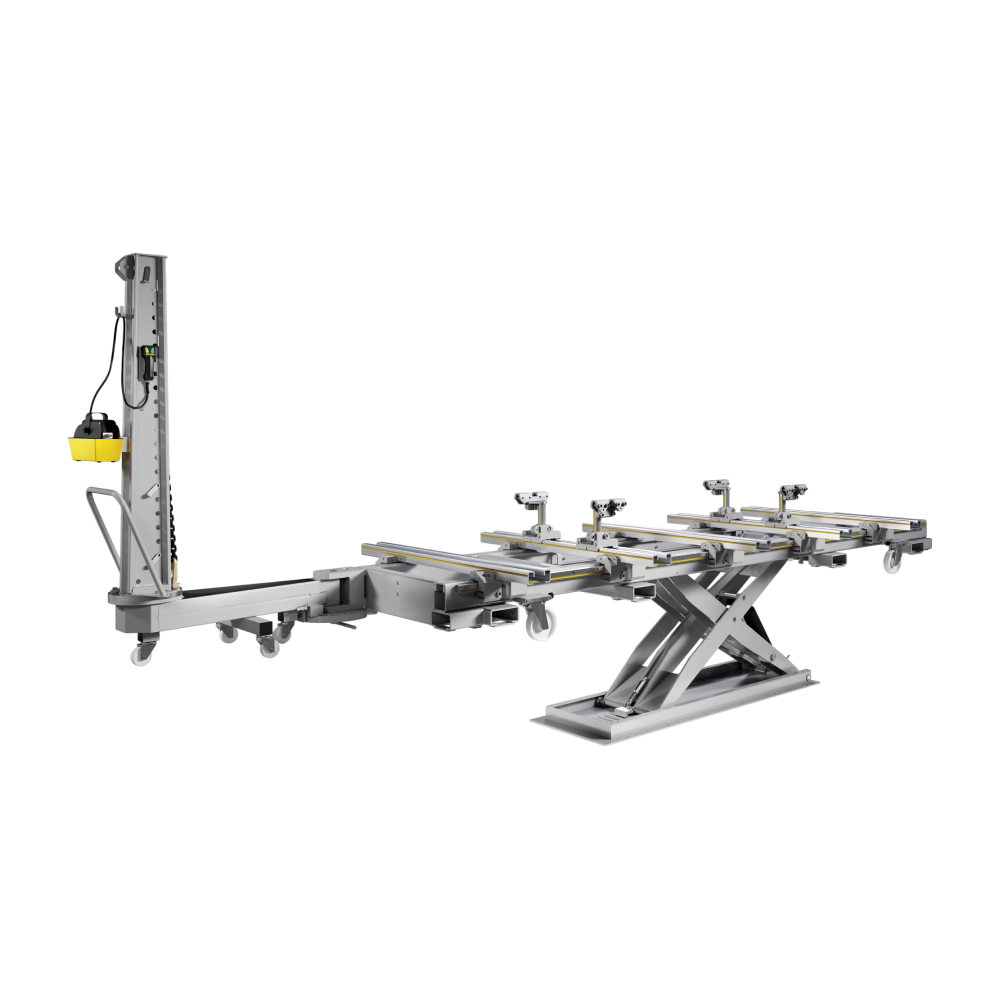

Frame Machine & Lift

The 100 TS provides even more versatility with the addition of a lift, ramps, and a loading trolley.

| 100 TS Components: |

|---|

| Bench w/ Rack Gears |

| Lift w/ Control Box |

| Pulling Column |

| Loading Trolley |

| 5 Crossbars |

| 4 Universal Clamps |

| Ramps |

Frame Machine & Lift

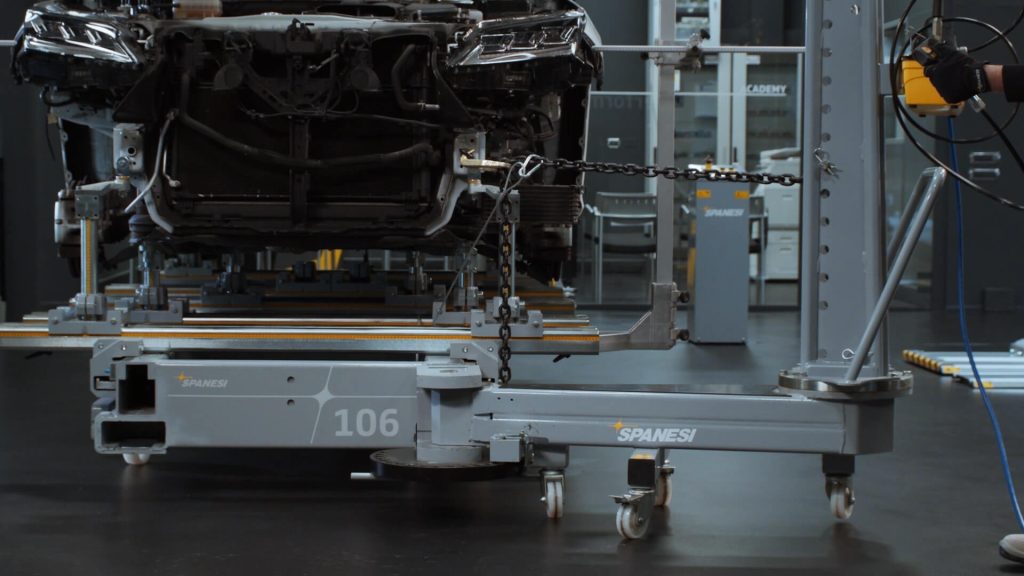

The 106 takes the 100 Series to the next level with the included lift and Universal Jig System.

| 106 Components: |

|---|

| Bench w/ Rack Gears |

| Lift w/ Control Box |

| Pulling Column |

| Loading Trolley |

| 5 Crossbars |

| Universal Jig System |

| Ramps |

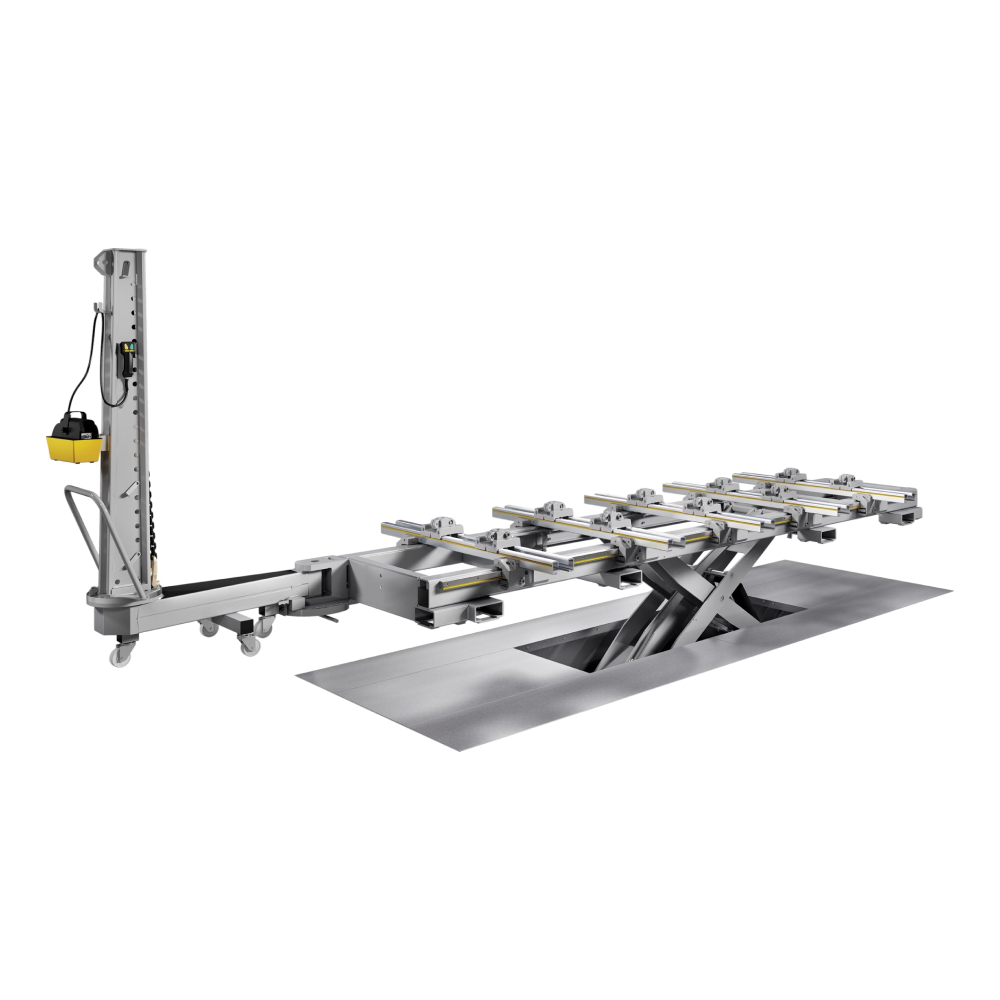

Frame Machine & Lift

The 106 PLUS is designed to be installed below the floor surface to enable maximum floor space within the collision repair facility.

| 106 Plus Components: |

|---|

| In-floor bench w/ rack gears |

| Lift w/ control box |

| Pulling Column |

| Loading Trolley |

| 5 Crossbars |

| Universal Jig System |

| Ramps |

Frame Machine & Lift

The 106 EXT is designed for longer vehicles. With length of 19′ 8″, it is suitable for work on vans, SUVs, and light/medium duty trucks.

| 106 EXT Components: |

|---|

| Bench w/ Rack Gears |

| Lift w/ Control Box |

| Pulling Column |

| Loading Trolley |

| 6 Crossbars |

| Universal Jig System |

| Ramps |

100 Series Frame Machines

| 100TB | 102 | 100TS | 106 | 106+ | EXT | Bench w/ Rack Gears |

|---|---|---|---|---|---|---|

| Pulling Column | ||||||

| Crossbars | 2 | 5 | 5 | 5 | 5 | 6 |

| Clamps / Jig System | 4 Clamps | Jig System | 4 Clamps | Jig System | Jig System | Jig System |

| Length | 13' 1" / 16' 4" | 13' 1" / 16' 4" | 13' 1" / 16' 4" | 13' 1" / 16' 4" | 13' 1" / 16' 4" | 19' 8" |

| Width | 5' 11" | 5' 11" | 5' 11" | 5' 11" | 5' 11" | 5' 11" |

| Lift w/ Control Box | ||||||

| Lifting Height | 5' 3" | 5' 3" | 3' 3" | 3' 3" | ||

| Load Capacity | 11,000 lbs | 11,000 lbs | 11,000 lbs | 12,000 lbs | ||

| Loading Trolley | ||||||

| Ramps | ||||||

| In-Floor Option |

Strong. Durable. Advanced.

Optional

Get more out of your 100 Series with optional accessories from Spanesi. Extend the capabilities of our structural repair workstation and improve product offerings and technician efficiency.

Click each accessory to learn more.

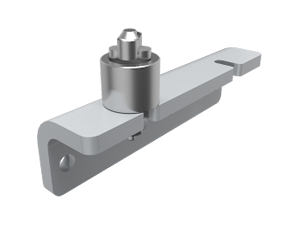

Device designed to allow for chain to pull down.

Special clamps designed specifically for BMW.

Telescopic Pulling Arm for 100 Series Benches.

Strengthened Electric Winch with 230v 50hz motor, .236″ diameter / .787″ length steel cable.

70.86″Crossbar with No. 2 Sliding Supports.

19.685″ extension for the vertical pulling column.

Platform to be utilized with the optional sixth crossbar.

Adapter to mount Minibench / Ponybench pulling column onto 100 Series benches

Clamp kit designed specifically for high profile and 4WD vehicles.

Clamp kit for high profile / 4WD vehicles (rear mechanics anchoring).

Elevate your body shop with Spanesi. Our 100 Series frame machines are designed to handle even the most difficult pulls.